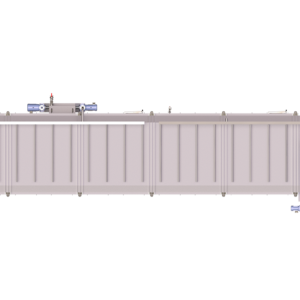

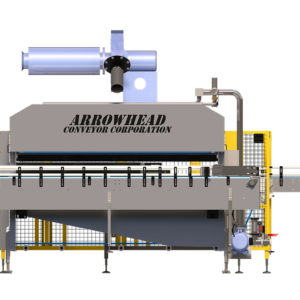

Spray Cooler

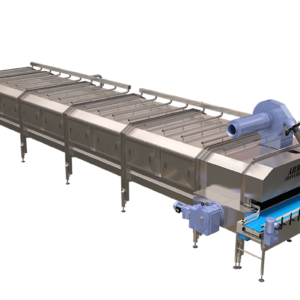

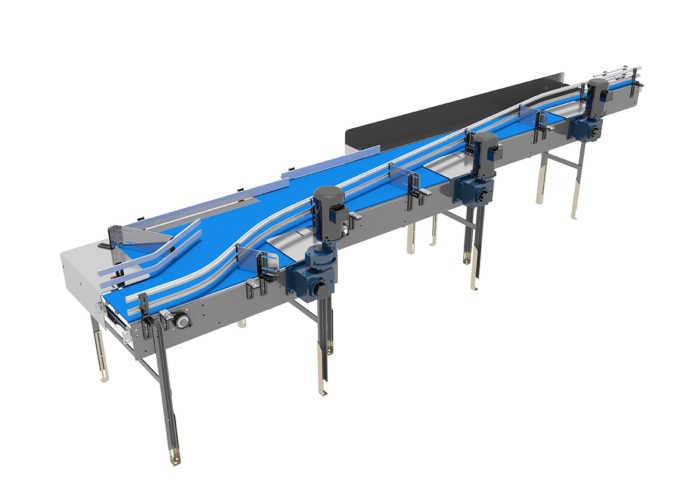

Meet your most demanding hot-filled container sanitary processing requirements with Automation Solutions Spray Cooler. Choose from a number of water and energy conservation options available to keep operating costs down. Cleaning is fast and easy with a sloped sump bottom with large access doors and basket strainers at suction points. Our patented Tab Lock Slide Bed design makes wearstrip changes fast and easy, and isolation valves allow quick-change pump maintenance.

- Thermal Testing: State-of-the-art Thermal Testing Lab and mobile testing equipment for product validation

- Maintenance: Low maintenance to help you reduce total operating costs

- End Product: Can be used to convey cans, bottles, pouches and bags

- Adjustability: Modular design allows flexibility to meet future production requirements

- Easy Installation: Easy to install as systems are shipped for quick installation without onsite welding

Engineering Services

With A&B Engineering, you get 24/7 support, call 844-686-5589 for project management, training, installation, relocation and more.

Questions? Contact us today.

Machine Specifications

End Product Details

Type

Bottles, Cans

Shape

Non-Round, Round

Fill

Cold-Filled, Full, Hot-Filled

Material

Aluminum, Glass, Plastic, Steel

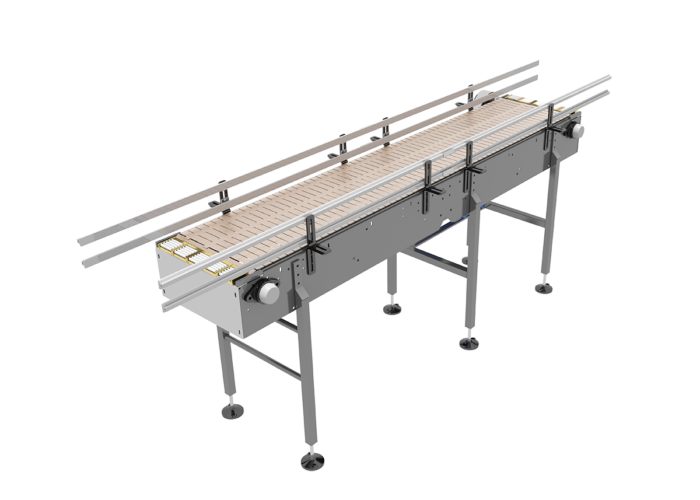

General Design

Modular

Yes

Frame

Open Frame

Material

Stainless Steel

Return

Serpentine

Wearstrip

Type

UHMW, Steel

Motor/Drive

Type

Wash Down, Stainless Steel Wash Down

Type 2

Gear Motor, Inverter Duty

Style

Shaft Mounted

Supports

Material

Stainless Steel

Construction

Formed Channel

Adjustment Type

Adjustable Foot

Adjustment Increment

3"

Warranty

Warranty

1 Year Warranty

Related Products

Engineered Solutions

Cutting Edge Technology

With A&B Engineering, you get 24/7 support.

New equipment not in the budget? A&B’s Engineering Services engineered solutions will extend the product life span of older, legacy equipment by modernizing your machines and increasing productivity.