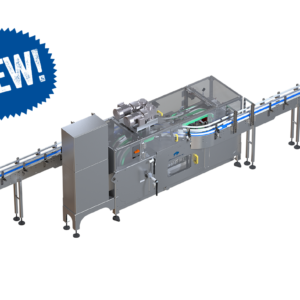

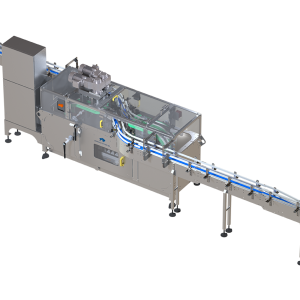

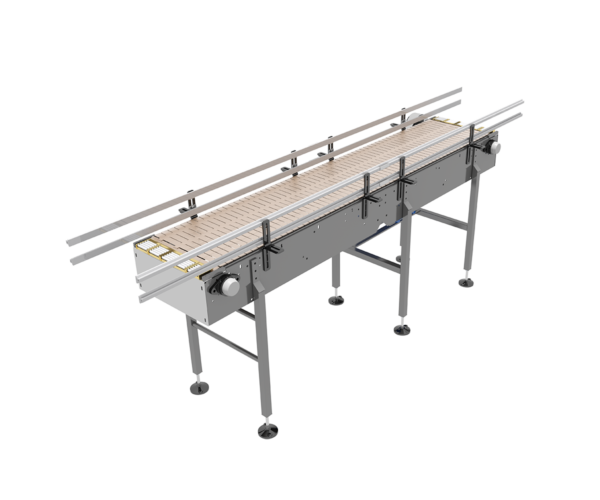

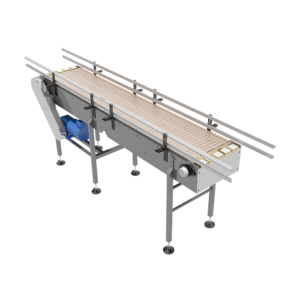

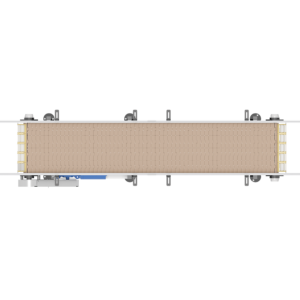

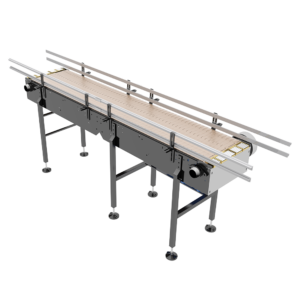

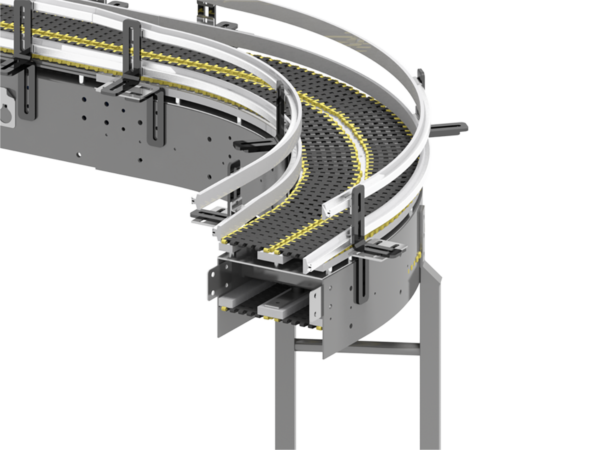

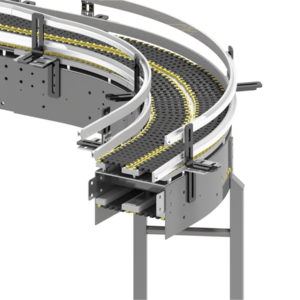

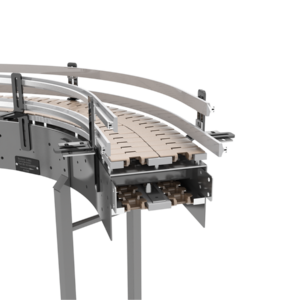

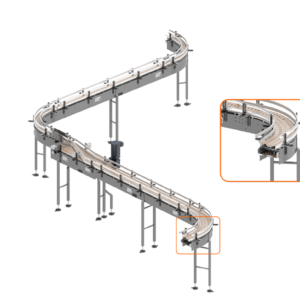

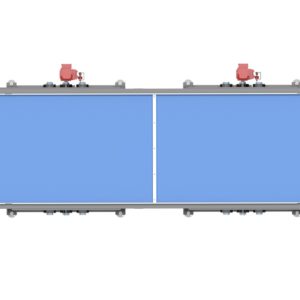

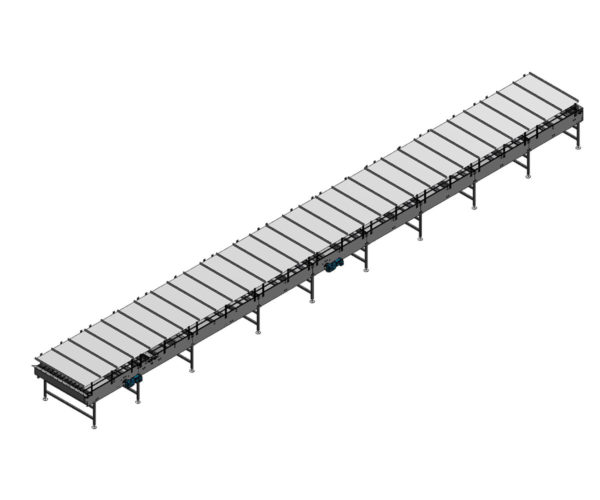

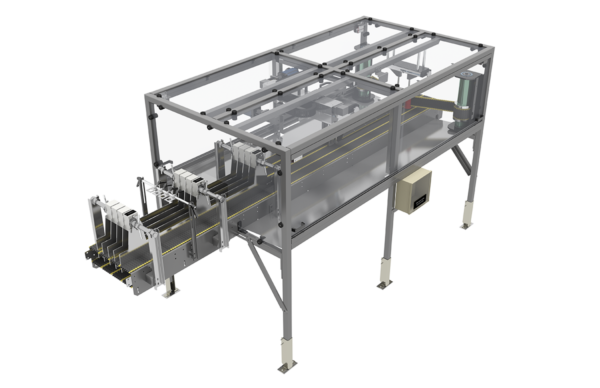

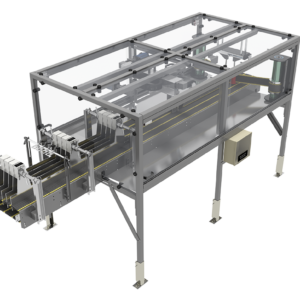

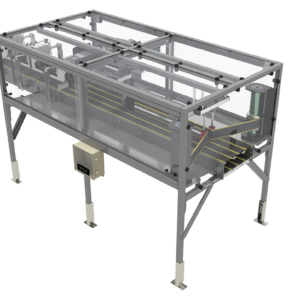

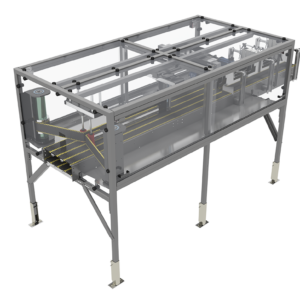

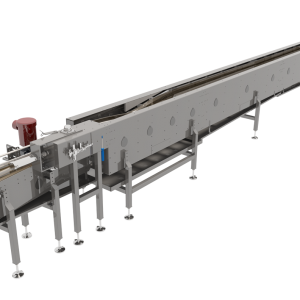

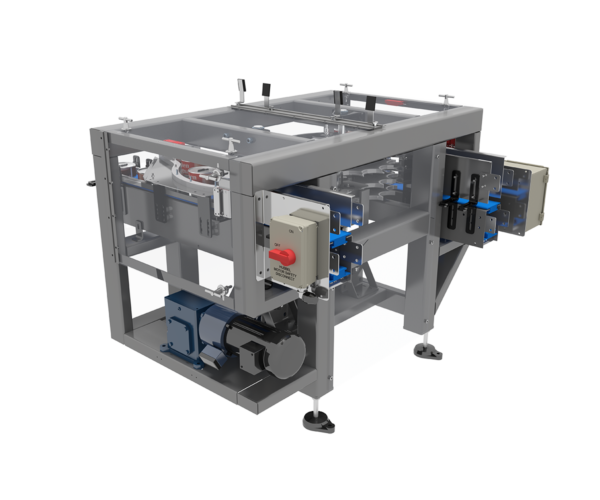

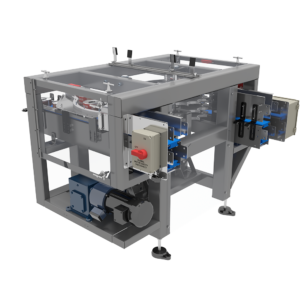

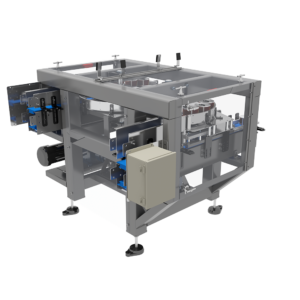

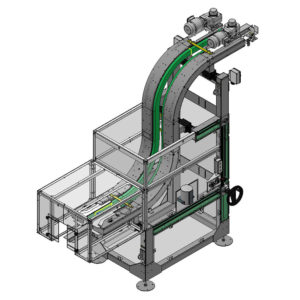

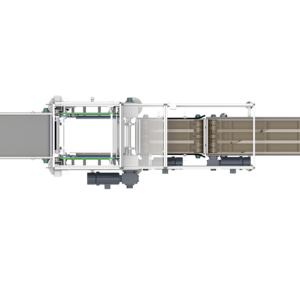

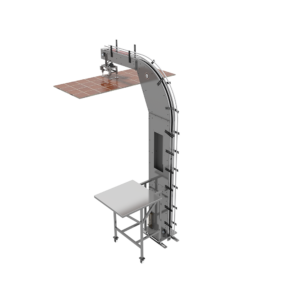

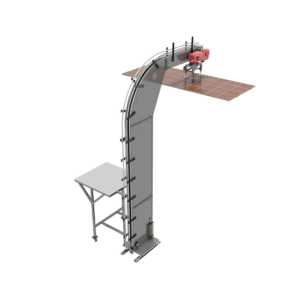

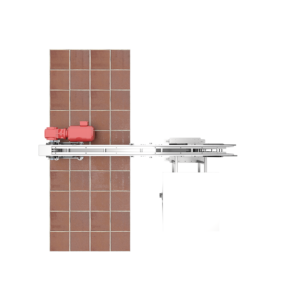

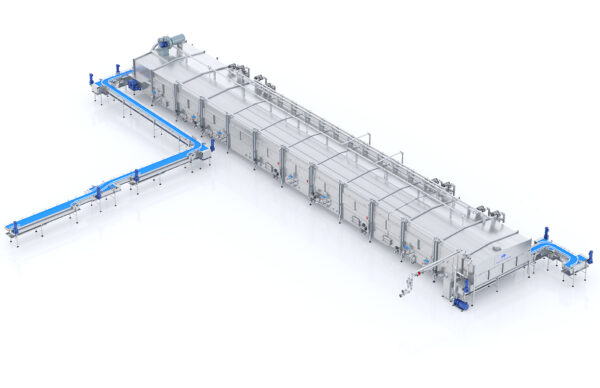

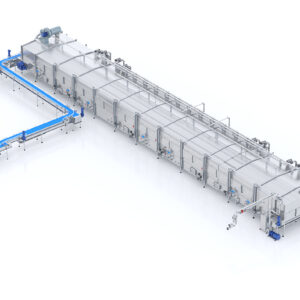

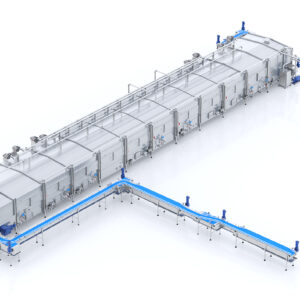

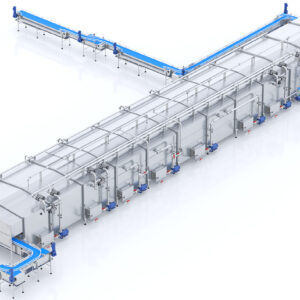

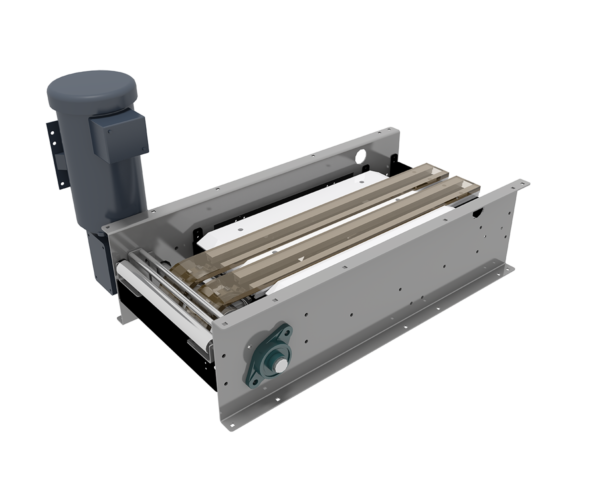

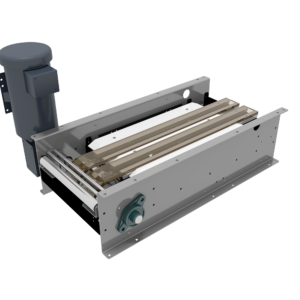

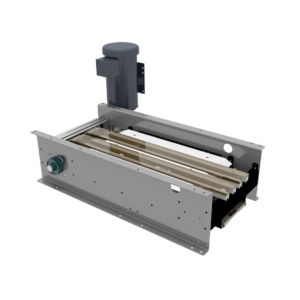

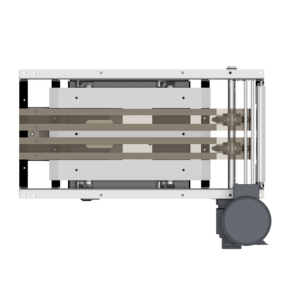

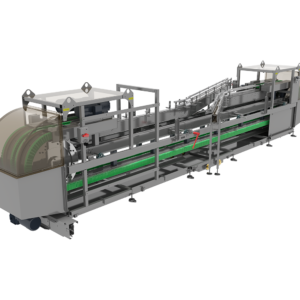

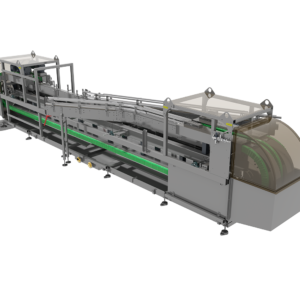

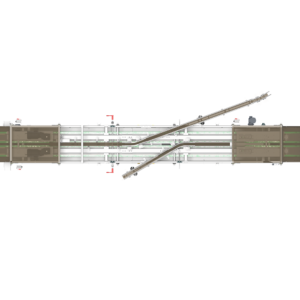

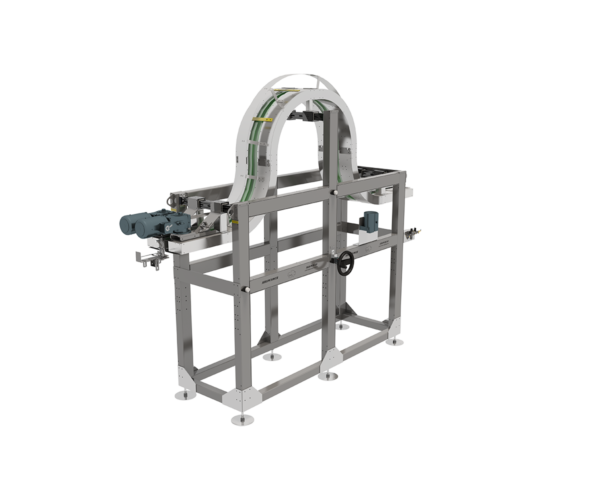

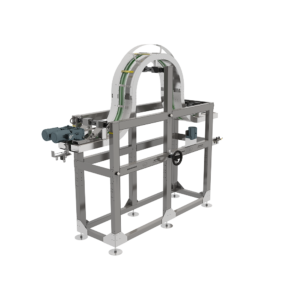

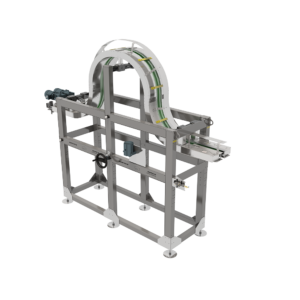

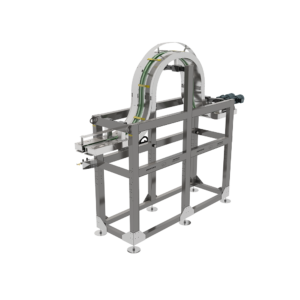

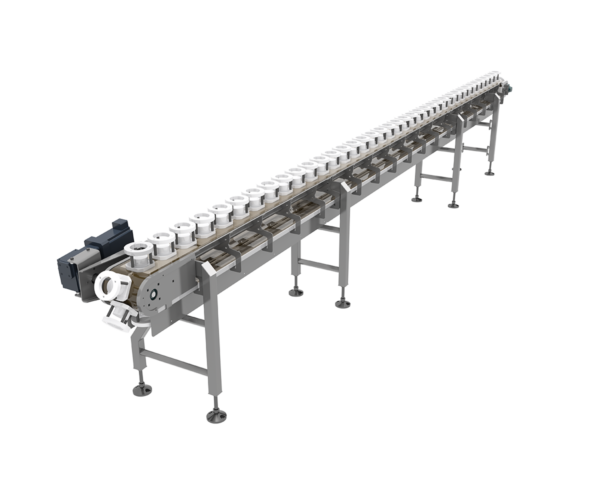

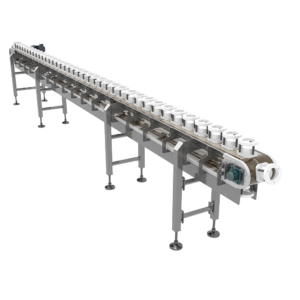

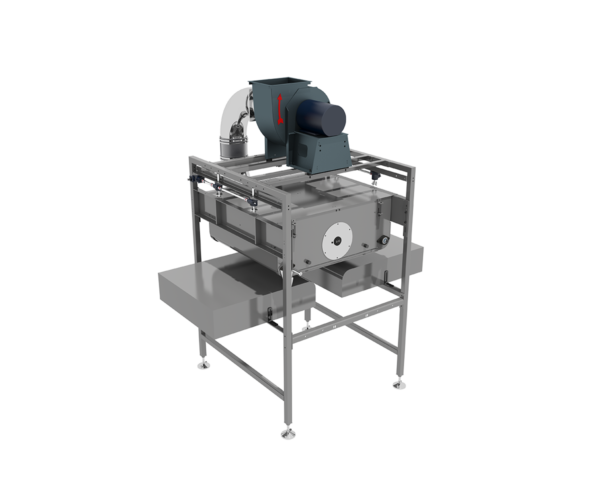

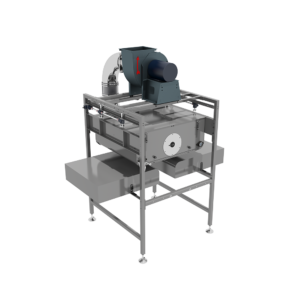

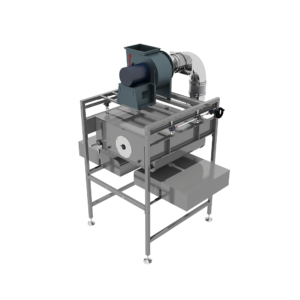

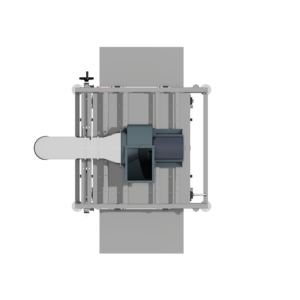

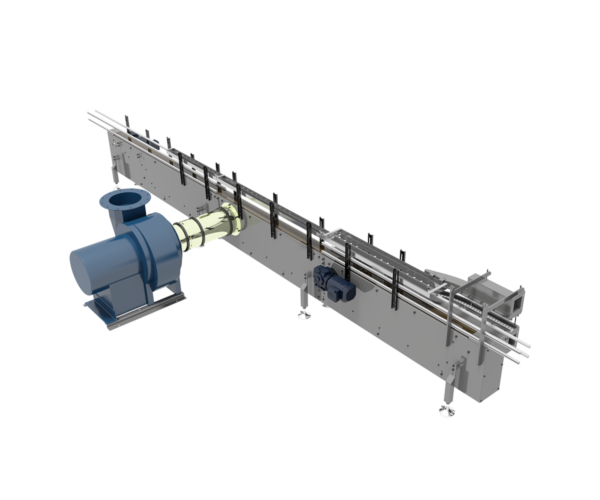

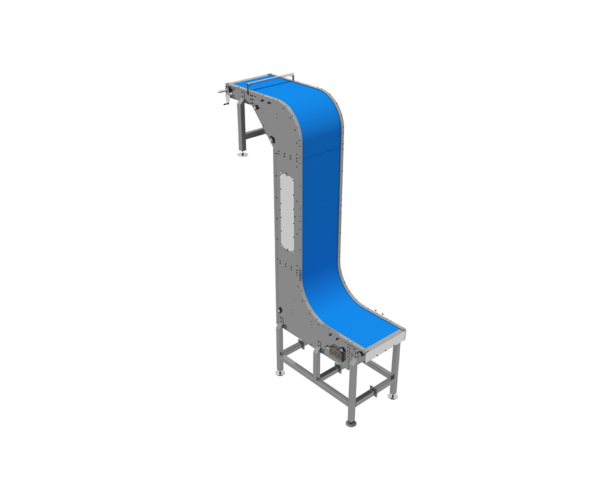

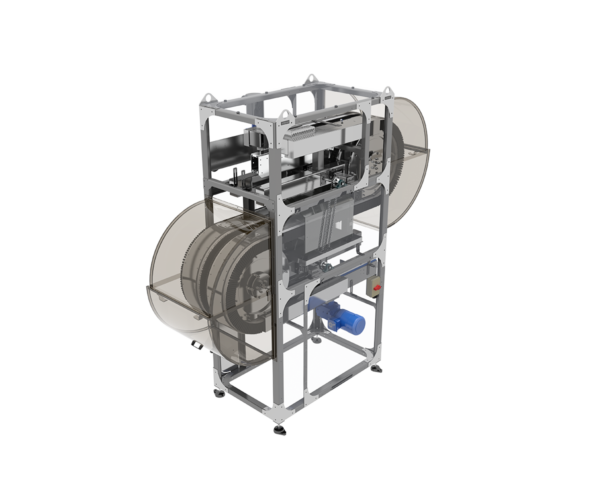

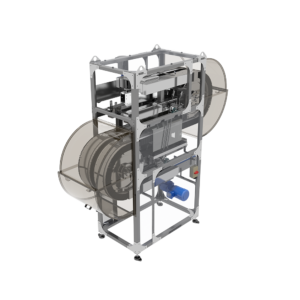

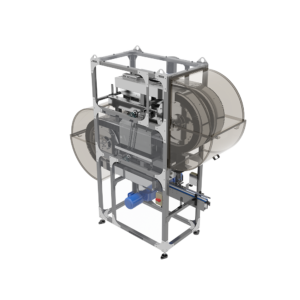

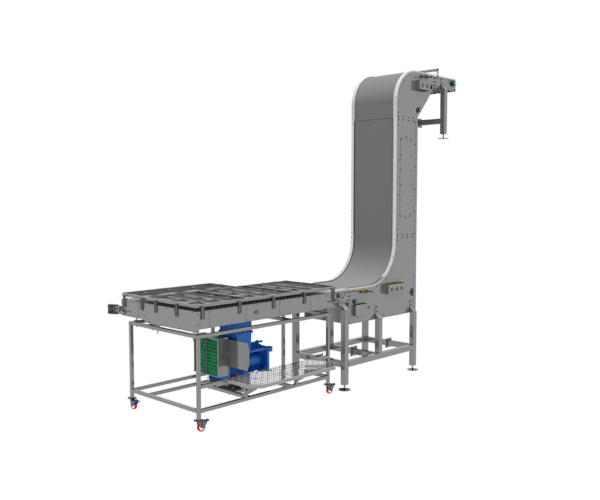

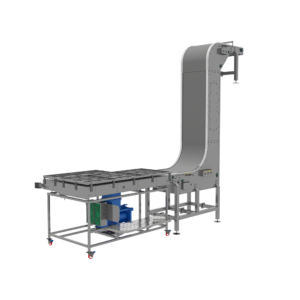

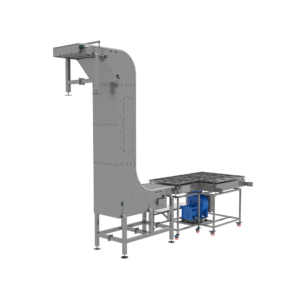

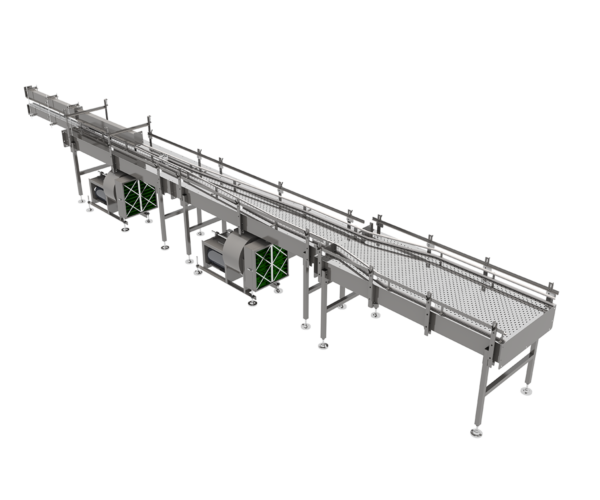

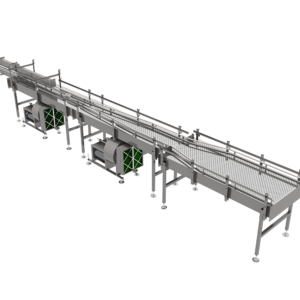

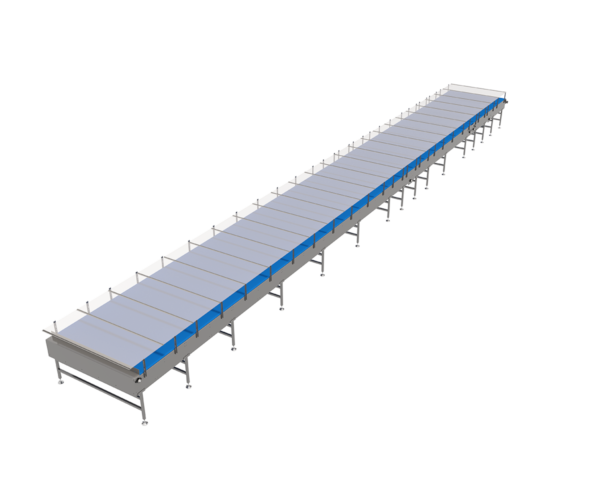

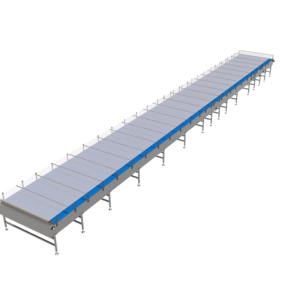

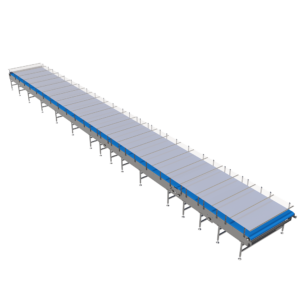

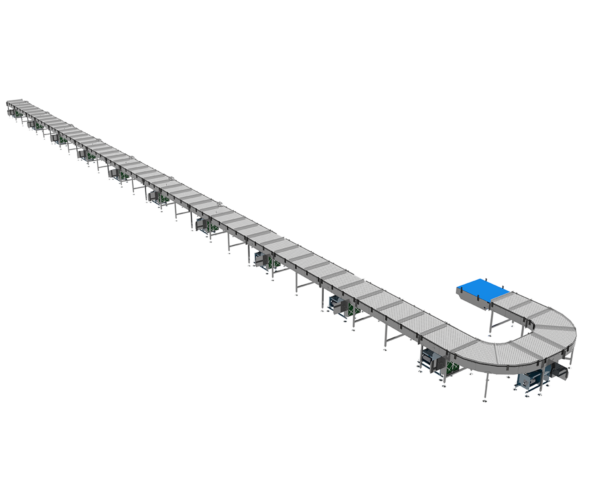

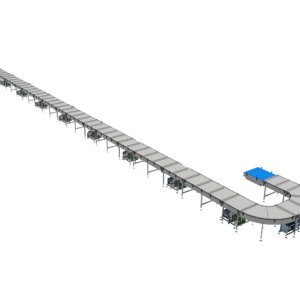

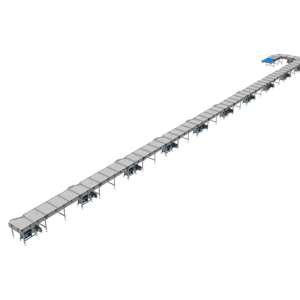

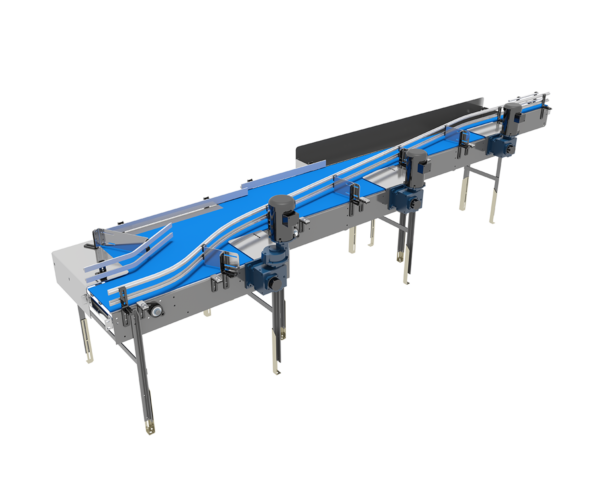

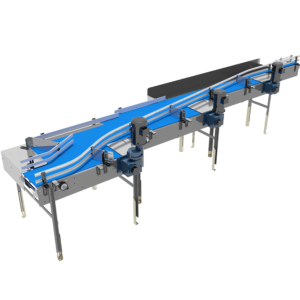

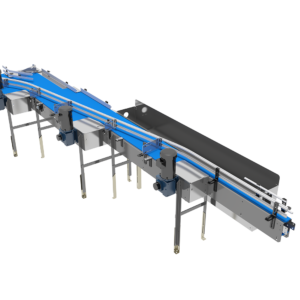

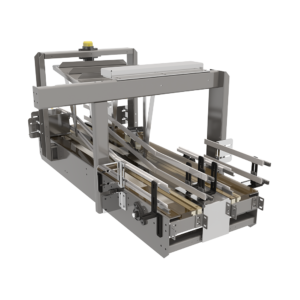

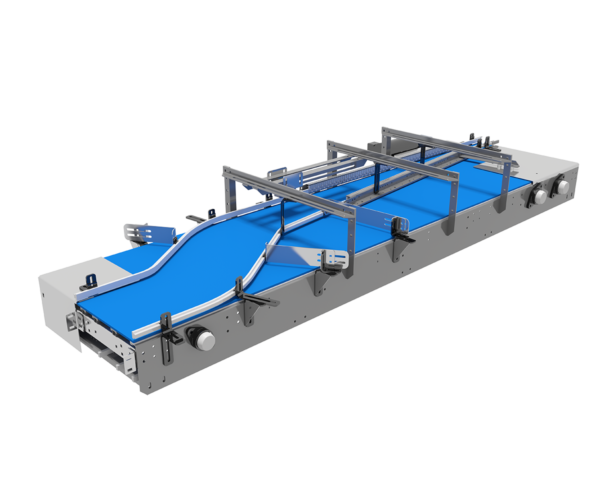

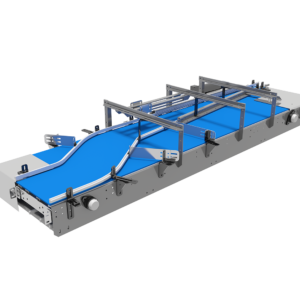

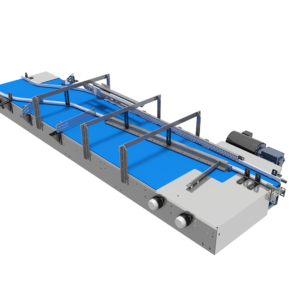

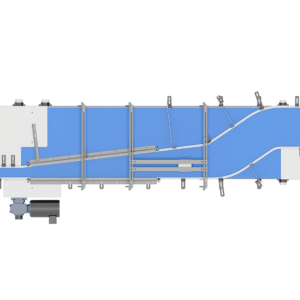

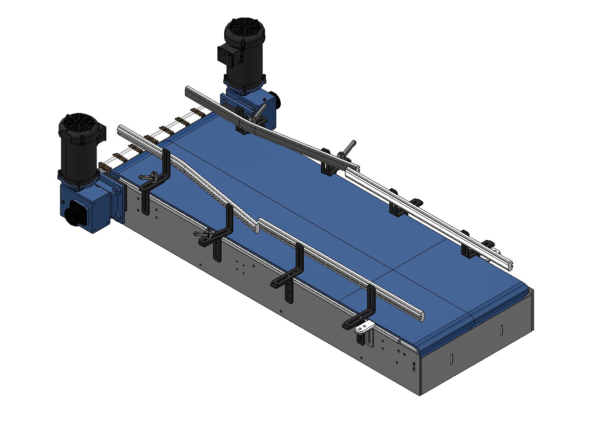

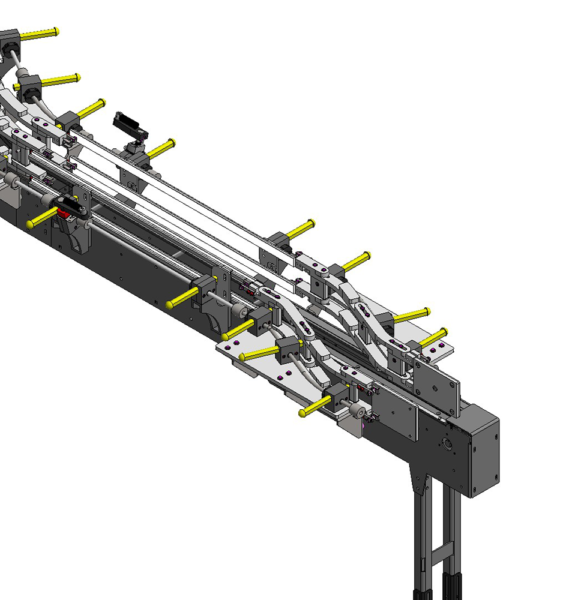

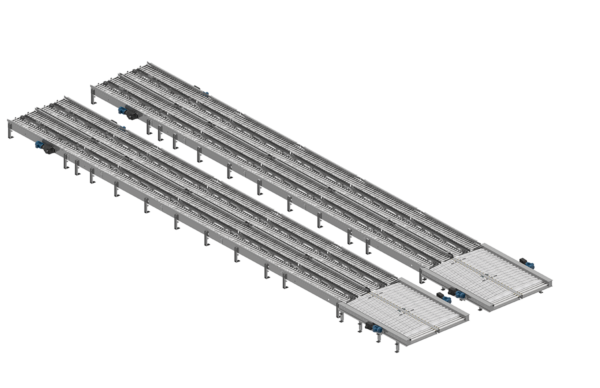

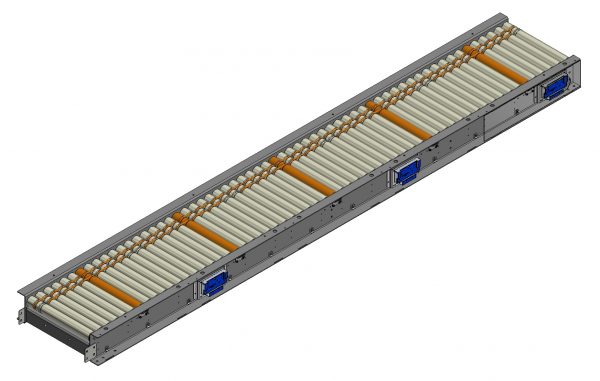

DIVERT & TRANSFER MODULE

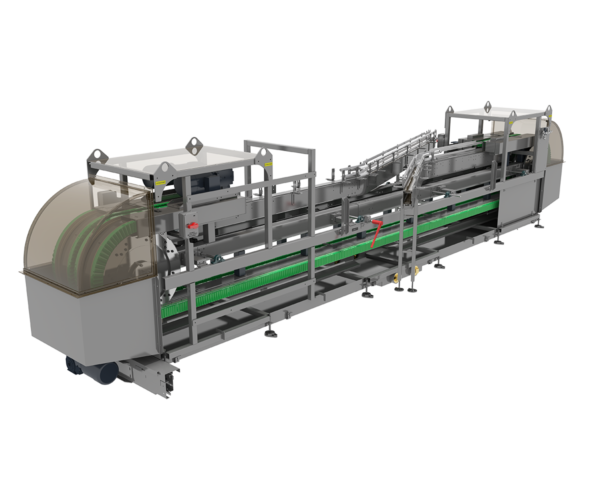

ModSort® Divert & Transfer Conveyor

- Standard Rates: Package rates of 35-50 per minute

- Typical Package sizes: Less than 30” x 30” & Weight of 50 lbs or less

- Safety: Quiet, safe, low maintenance, 24 volt

- Easy Installation: Can be added to an existing or new conveyor system and utilizes industry standard 24V connections to help ease installation in your application.